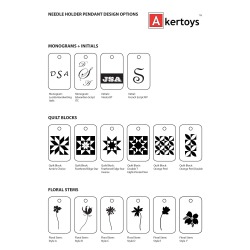

[Adan] This was a quick project for a family member's storefront window: the previous sign had met with an untimely end, and this was an opportunity to do a rapid design-build blitz to make a new one. Here's what we came up with:

Pretty slick, huh? You'll never guess what it says on the other side:

Well, okay, I concede you may have guessed that one. We at Akertoys like to boast of having an above-average viewership. Small, but above-average!

The two faces were V-carved to 0.075" (approx. 2mm) deep, then the entire board was painted and left to dry. Then everything inside a 1/4" perimeter was pocketed down by 0.020" (approx 0.5mm). That left a nice border, and a stark contrast between the letters and the bare beech around them.

The base plate is identical in size and shape to the sign plate. It serves as a mount for the two side braces, which are dowel-aligned and held on with two screws each. By the way, have I mentioned how much I love

McFeely's square-drive screws? If you've never tried them, get their sampler pack - it's magnificent. The square drive is so superior to phillips, and the screws are high quality and have a nice deep thread, perfect for strip-out resistance in wood. But anyway... I digress!

On the inside of the right side brace is a pocket into which is adhered a 0.5"x0.1" rare earth magnet. Two more of those wicked strong magnets are glued into the sides of the sign board (visible in the previous picture, not quite obscured by the paint). Believe me, I double- and triple-checked the polarity before sticking them in permanently.

That nice hovering effect is caused by the four non-slip rubber feet on which it's resting. These were provided by my dad, who came to the rescue after I made a panicked last-minute phone call: "Help, do you have any rubber feet??" Oh, and that hole in the middle of the underside? That was where the magnet was going to go, before I decided I'd prefer to have it off to the side. That change made the magnets on the sign board slightly less prominent. Mid-course design change, very exciting.

And finally, here's a video of it doing its thing. Enjoy!