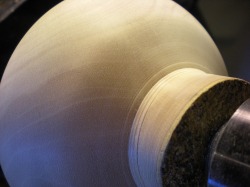

Ian asks, and answers: "What do you make when you got a lathe for Christmas and an Easy Rougher for your birthday? An Egg, of course!!"

That's pretty much exactly egg-sized... which is hilarious because Ian began this turning exercise with a chunk of oak sized for the fireplace! He wanted to pick a challenging wood for the Easy Rougher, and what better than white oak from the fire pile? Then he started turning, and turning... and the chips were flying... and once you get the chips started flying you never wanna stop... and now all that's left is this lovely egg, all smooth and buttered up with some beeswax.

Very nice.

(Adan) More playing with the lathe: I went down this morning and made a quick little cup out of the stump left over from the second top I made (day before yesterday). These tops and cups are fun and simple. My turning skills are pitiful at best, but hey: good enough for these little joys!

The turning process is pretty basic. At the moment I'm trying to just get the feel of things without going crazy and trying all the tools. As such, I'm using only a parting tool, skew, and scraper. Any self-respecting turner is groaning in pain upon reading that, I'm sure... but it's a start. I'll learn, just need a little time.

One first: this time, before boring out the hollow of the cup, I used a drill to cut a 1/2" hole in the middle. This makes the boring much easier, since you're not messing around with the zero-velocity nibs in the middle. This was previously impossible, though, as we had no tailstock chuck. Yesterday, however, I purchased a MT2 (Morse Taper #2) compatible keyless chuck... and then today, impatient for that to arrive, I researched and found our drillpress already has an MT2 taper on its chuck! So I knocked the chuck out of the drillpress and slapped it onto the lathe. Happy times ensued. There's something truly fascinating about watching a non-rotating drillbit draw curly chips out of a spinning workpiece.

So that was a little video showing the newer of the two tops spinning in its cup. The cup really isn't an ideal place for the top, but it does make some interesting wobble patterns! What do you think?

(Adan) Yesterday afternoon saw Ian and me hoisting his new lathe up onto a brand new stand we had just fabricated for it. Check it out, it's quite glam:

As glam, that is, as a stand can be when it is constructed out of a sawhorse and a 2x12! It was pretty wobbly after those initial two elements were joined, so we added the sheet of plywood you see at the bottom. That stiffened it up considerably. After a couple of sticks braced the baseplate down to the feet of the horse, it was like a rock. Sort of. Close enough, we said, and we started making some chips.

This is a "bowl" of sorts, I guess? We took turns reducing a large chunk of holly down to this size. We also tried gouging out its interior just a bit:

Pretty cool, huh? It will probably never be a completed bowl, unfortunately, but you never know. It was great fun as a practice piece.

This was my first piece. What can I say, Jennifer and I just saw Inception... what else was I going to make?? We don't have a chuck or faceplate that fits this lathe yet (on order, coming soon, don't worry), so getting this down to a point was a bit tricky.

It was a lot of fun. We don't, as a company, have a lot of need for turned parts quite yet... but we got so much entertainment out of making these little guys, we may need to invent some axisymmetric parts, post haste. Now we just need to make sure we don't get used to that "stand" and leave it there forever. Temporary, it's only meant to be temporary.